What is Heat Pipe?

A heat pipe is a simple device that can quickly transfer

heat from one point to another, which is usually used for cooling an

electronic component in air-conditioners, refrigerators, heat

exchangers, transistors, capacitors, etc. Heat pipes are also used

in laptops to reduce the working temperature for better efficiency.

A efficient heat pipe system can be affected by length of a heat

pipe, type of fluid in a heat pipe, return wick type, and the number

of bends in a heat pipe. Its small, compact profile, light weight,

and cost effective heat pipe solution allow it to meet the demanding

requirements of laptops.

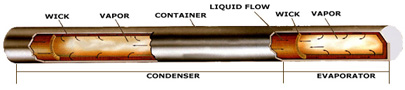

Heat Pipe Structure:

A heat pipe is consisting of following three basic

components:

1. container

2. the wick or capillary.

3. the working fluid

First, the container is a

sealed, hollow tube, which can isolate the working fluid from the

outside environment and can maintain the pressure differential

across its walls, and enable transfer of heat to take place from and

into the working fluid.

Inside walls of the container are lined with a porous structure,

which is called capillary structure or wick. The prime purpose of

the wick is to generate capillary pressure to transport the working

fluid from the condenser to the evaporator.

Finally, the working fluid is contained in wick structured

container. The first consideration of choosing a suitable working

fluid is the operating vapor temperature range. Most pipes use water

and methanol/alcohol as working fluid.

How do Heat Pipes Operate:

One

end of the heat pipe attached to the heat source. As the heat rising

to the desired operating temperature, the tube boils the working

fluid and turns it into a vapor. As the evaporating fluid fills the

hollow center of the wick, it spreads throughout the heat pipe

toward to the other cold end. Condensation of the vapor occurs

wherever the temperature is even slightly below that of the

evaporation area. As it condenses, the vapor gives up the heat it

acquired during evaporation and the condensed working fluid is then

sucked back to the evaporating section along the wick structure.

This thermodynamic cycle continues and helps maintain constant

temperatures.

Attaching a heat sink

to a portion of the heat pipe makes condensation take place at this

point of heat loss and establishes a vapor flow pattern. Capillary

action within the wick returns the condensate to the evaporator

(heat source) and completes the operating cycle.

Features :

Provide high thermal conductivity with small temperature difference

Fast thermal response

Small size and light weight

Large variety of shapes

No electrical power supply required, and maintenance free

Reduce overall system size and costs |